Sheet Metal Fabrication

Our sheet metal department is fully equipped with the latest equipment to meet your demand. Unless otherwise noted, everything is performed in house.

Our sheet metal department is fully equipped with the latest equipment to meet your demand. Unless otherwise noted, everything is performed in house.

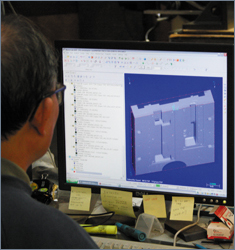

USK's machining facility is fully equipped for custom fabrication of stock to finished product or modifying existing parts. Milling, turning, threading, and boring capabilities of up to 0.0001 (.003 mm) tolerances are possible with the recent addition of new state of the art equipment. Our machines are capable of milling 30x84 inches, turning parts 6x15 inches and surface grinding parts 15x30 inches.

USK's machining facility is fully equipped for custom fabrication of stock to finished product or modifying existing parts. Milling, turning, threading, and boring capabilities of up to 0.0001 (.003 mm) tolerances are possible with the recent addition of new state of the art equipment. Our machines are capable of milling 30x84 inches, turning parts 6x15 inches and surface grinding parts 15x30 inches.

Our machine shop takes pride in its years of experience, which is essential for accuracy, efficiency, and punctuality. Combining our years of experience with our CNC and CAD software allows us to produce top quality products in the shortest amount of time. Some of our products include screws, pulleys, bolts, couplings, mounts, flanges, washers, nuts, fittings, heat sinks, rollers, shafts, bushings, clamps, levers, wheels, posts, guides, sleeve bearings, and frames.

We specialize in parts that demand that extra attention to detail which makes us perfect for military, aerospace, and government jobs. We work from bar, rod, plate, pulley stock, castings, angles, channels, extrusions, you name it. Our experienced technicians will reduce material waste, shorten labor time, and pass these savings on to you.

To complement our creation of metal and plastics fabrication, we have a department dedicated to the assembly of any parts and components you may demand. As a turnkey manufacturer, we can fabricate and assemble your entire product using fasteners or adhesives. With years of assembly experience, we will work with you to have your product assembled exactly how you like it with meticulous attention to detail.

To complement our creation of metal and plastics fabrication, we have a department dedicated to the assembly of any parts and components you may demand. As a turnkey manufacturer, we can fabricate and assemble your entire product using fasteners or adhesives. With years of assembly experience, we will work with you to have your product assembled exactly how you like it with meticulous attention to detail.

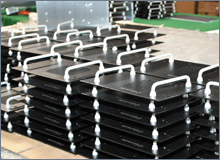

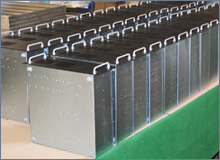

Our assembly work usually consists of fastening panels, gaskets, brackets, handles, electrical components, switches, latches, meters, valves, fittings, bumpers, locks, wheels (caster), clips, springs, etc. We also do minor electrical assembly work such as inserting fans, soldering, and wire harnesses. Some of our past work includes semi-conductor equipment, medical carts, computer chassis, and dollies.

We are a one stop shop for all your manufacturing needs. We can purchase all the needed components for the customer or they may provide it as well for the assembly process. With this in mind, our large facility is perfect for both low and high quantities of assembly. As always, strict quality control protocols are ensured for your high quality product. USK never takes shortcuts such as using improper tooling for the job. Seen below are a few examples of our assembly work.